Digital Twins: How Virtual Copies Of Real Objects Work

Have you ever wished you could test something without actually risking anything in real life? I remember once when my washing machine started making a weird rattling sound. I stood there thinking, if only I had a digital version of this thing to figure out what went wrong before taking it apart in real life. Little did I know the world was already moving toward that kind of magic through something called digital twins.

Today, digital twins are becoming one of the most talked about technologies in industries like manufacturing, healthcare, transportation, and even smart homes. The idea sounds futuristic at first. A virtual copy of a real object that behaves just like the real thing. But the more you understand it, the more it feels like one of the smartest concepts humans have ever created.

So grab a cup of coffee and let us walk through this incredible world of digital twins and explore how they work, why they matter, and how they may soon become a part of everyday life.

What Are Digital Twins

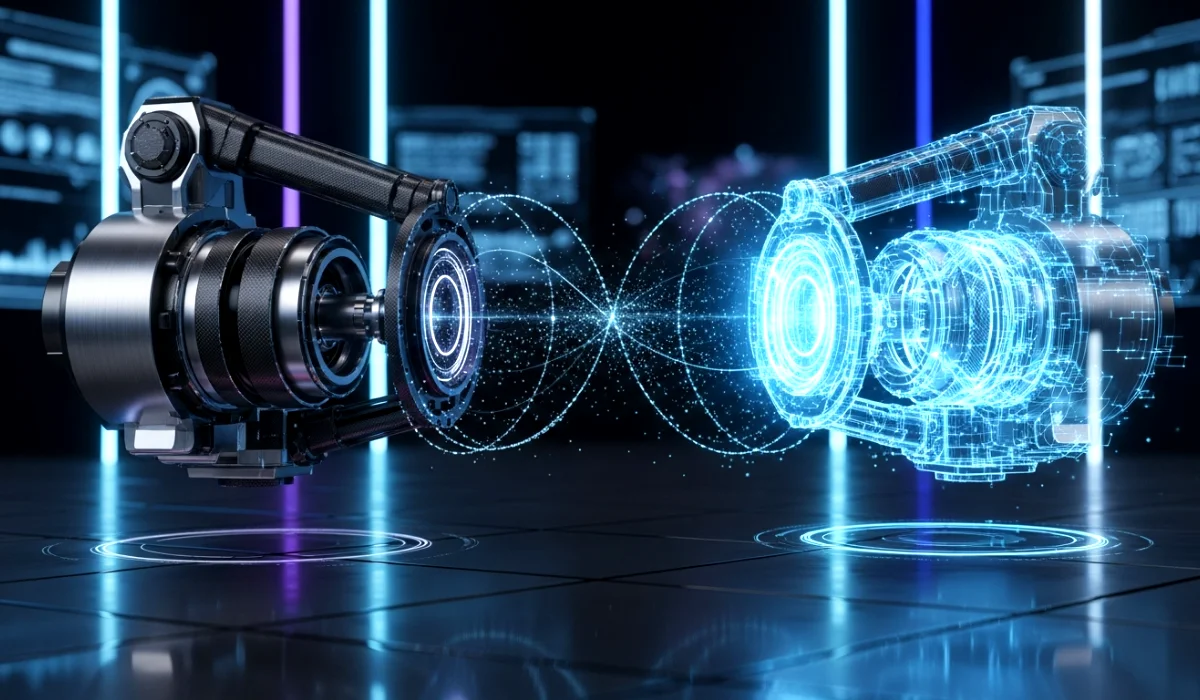

Digital twins are virtual replicas of real world objects, systems, or even entire environments. Think of them as detailed computer models that do more than simply look like the original. They act like the original too.

Imagine a virtual airplane engine that can show real time temperature, pressure, vibration, and performance patterns. Or a digital twin of a building that reveals airflow, electricity usage, and movement of people inside. These twins are not ordinary simulations. They constantly receive live data from sensors placed on the real object. That means the digital version mirrors the behavior of the physical object with impressive accuracy.

When I first heard about this, I had the same reaction many people have. Why would anyone need a virtual copy when the real one is right there But once you dive deeper, the benefits become obvious. Instead of experimenting on the real object and risking damage or losing money, you can do all the testing inside the digital world safely.

How Digital Twins Actually Work

Understanding digital twins is much easier when you break them down into their core components. If you have ever synced your phone with a smart watch, that is basically the idea. The real object and the digital version keep talking to each other through constant data exchange.

You can also read : Ways To Reduce Carbon Footprint Of Your Gadgets

Here is the basic workflow.

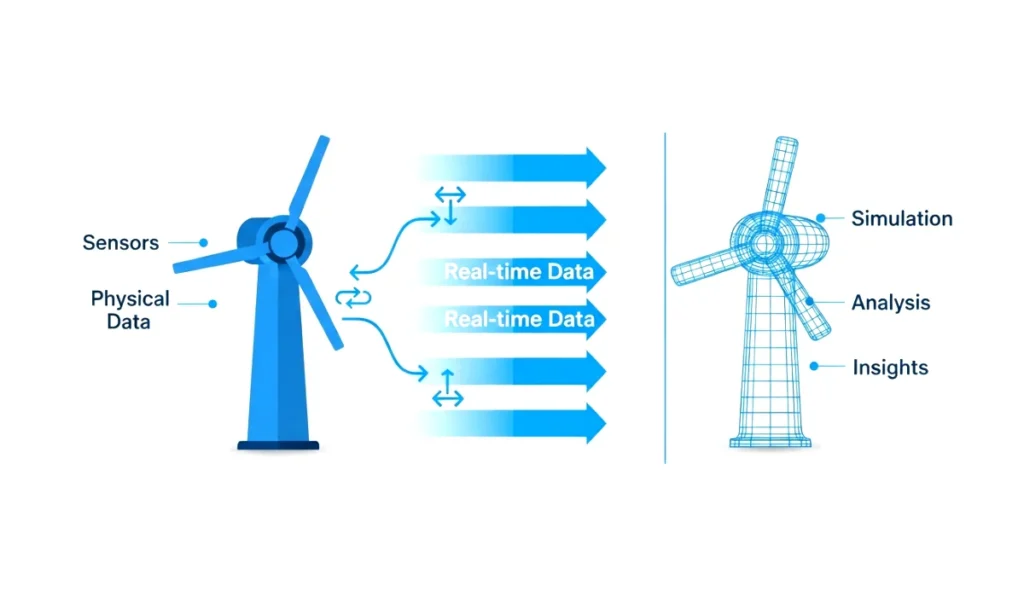

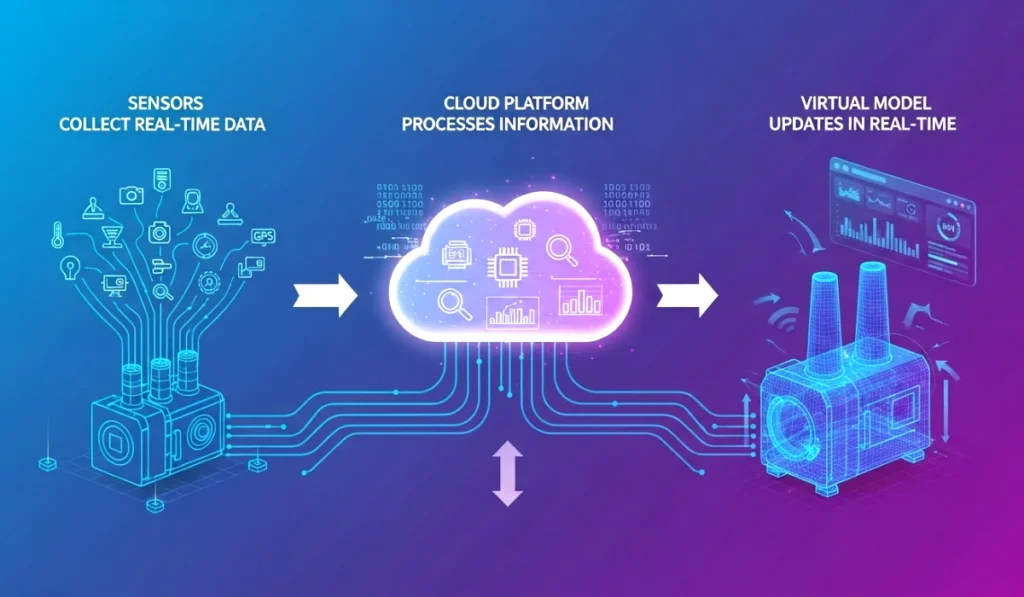

1. Sensors Collect Real Time Data

The physical object, whether it is a car engine, a factory machine, or a human organ, is fitted with sensors. These sensors measure things like temperature, speed, pressure, movement, or even chemical changes.

2. Data Travels To The Cloud Or A Processing System

The data collected by sensors moves to a digital platform through the internet or secure networks.

3. A Virtual Model Is Created

Engineers or software create a detailed digital version using advanced modeling tools. This is the digital twin.

4. The Digital Twin Continues To Update

As new data comes in, the digital twin keeps changing and adapting to match the real object.

5. Predictions And Insights Are Generated

This is where the magic happens. Using artificial intelligence, analytics, and simulations, the digital twin can predict failures, suggest improvements, or show how the object will behave under different conditions.

It is like having a virtual crystal ball that shows you what might go wrong before anything actually happens.

Why Digital Twins Matter In Modern Industries

Every time I talk to someone about digital twins, I notice the moment their eyes widen. It usually happens when they realize how much time, money, and risk can be saved. If businesses can run tests in the digital world before touching the real world, that is a game changer.

Here are some areas where digital twins already make a massive difference.

Digital Twins In Manufacturing

Manufacturing companies were among the first to adopt digital twins because they rely heavily on machines and equipment. A small failure inside a factory can cost millions. Imagine if a critical machine stops working in the middle of production. Everything halts. Workers wait. Deliveries get delayed. Customers get upset.

With digital twins, companies can predict these failures before they happen. A virtual model of every machine shows which parts are wearing out, how much maintenance is needed, and what might go wrong. Manufacturers can run tests without stopping the real machines.

Factories also use digital twins to design new products faster. Instead of building a dozen prototypes, engineers create digital versions and test them virtually. It saves time, reduces costs, and speeds up innovation.

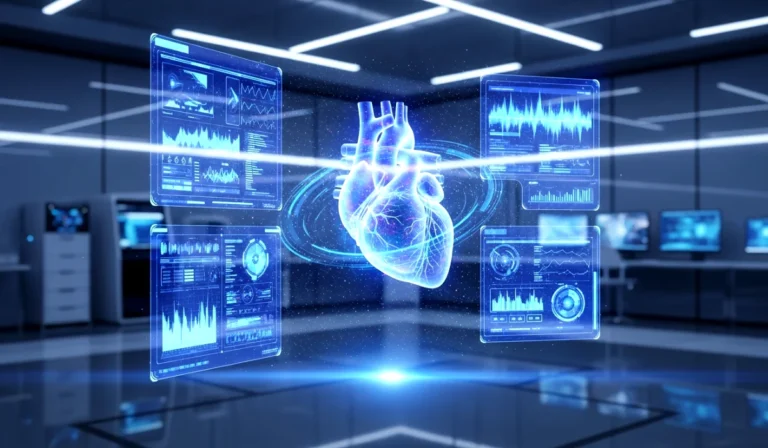

Digital Twins In Healthcare

Now this is where things get emotional. Healthcare is one of the most meaningful areas for digital twins. Some hospitals already use digital twins of organs like the heart to understand how a specific patient might respond to certain treatments.

Imagine a digital twin of your heart that shows how blood flows through it. Doctors can adjust medications or test surgeries virtually to find the safest option. This can reduce risks and lead to personalized treatment plans.

Researchers are also building digital twins of entire human bodies. That means a future where doctors can predict diseases long before they become serious. It sounds like something out of a sci fi movie, but it is slowly becoming reality.

Digital Twins In Smart Cities

Cities of the future will rely heavily on digital twins. Think of a digital twin of a city that shows traffic, pollution levels, water pipelines, and energy consumption all in real time. Authorities can use this to prevent accidents, reduce traffic jams, design better roads, and even prepare for natural disasters.

Imagine knowing exactly which area of a city will flood first because the twin already predicted it. Lives could be saved. Resources could be used smarter. Cities could run more efficiently.

Digital Twins In Transportation

Transportation systems like cars, trains, and airplanes benefit from digital twins too. Car companies use them to improve design and safety. Airlines use them to predict maintenance needs for engines. Train systems use them to optimize schedules and avoid breakdowns.

If you have ever been stuck because a train was delayed due to technical issues, imagine a world where such problems are found and fixed long before they become a real problem. That is the power of digital twins.

Digital Twins In Real Estate And Construction

Construction projects are complicated. Hundreds of things can go wrong. Digital twins help architects and engineers see how a building will behave even before the first brick is laid.

A digital twin of a building can show:

- airflow movement

- structural stability

- electricity usage

- temperature flow

- emergency evacuation patterns

This means safer buildings, smarter energy use, and fewer surprises during construction.

I once visited a friend who is an architect, and he showed me a virtual model of a mall that had not even been built yet. Walking through that digital version felt so real that my brain forgot it was a simulation. That is the level of detail digital twins can achieve.

The Three Main Types Of Digital Twins

Not all digital twins are the same. They are usually divided into three types based on how much detail they contain.

1. Component Twins

These are digital versions of single parts like a car battery or a gear inside a machine.

2. System Twins

These represent a complete system made of many components, like an entire car engine.

3. Process Twins

These show how a full process works in real time, such as how a factory production line operates from start to finish.

Each type offers different insights and is used depending on the complexity of the job.

Benefits Of Digital Twins

There are plenty of advantages, but here are some of the biggest ones.

- Reduced risk during testing

- Lower maintenance costs

- Faster product development

- Better safety and performance

- Real time monitoring

- Improved decision making

- Personalized experiences for customers

When companies make smarter decisions, customers also receive better products and services. Everyone wins.

Challenges Of Digital Twins

No technology is perfect. Digital twins also come with challenges.

1. High Cost For Setup

Sensors, software, modeling, and data systems can be expensive.

2. Need For Skilled Experts

Building accurate digital twins requires engineers, data analysts, and IT specialists.

3. Data Security Risks

More data means more responsibility to protect it.

4. Complex Integration

Connecting real world machines to virtual systems is not always easy.

Still, even with challenges, the benefits overpower the limitations.

The Future Of Digital Twins

The future looks bright. Digital twins are expected to become a part of daily life. Soon you might have digital twins of:

- your home

- your car

- your appliances

- your fitness routine

- even your body

Brands will use digital twins to create personalized experiences. Smart homes may predict what you need before you even think about it. Cars may diagnose problems automatically. Fitness apps may learn how your body reacts and give smarter recommendations.

The world is moving toward a space where the real and the digital blend seamlessly. And honestly, it is exciting to imagine what this could bring.

Conclusion

Digital twins are transforming industries with their ability to create virtual copies of real world objects. These twins help predict failures, improve safety, save time, and reduce costs. From manufacturing to healthcare to smart cities, digital twins offer a smarter way to test, learn, and innovate.

So next time you see a machine working smoothly or a building designed perfectly, remember there is a good chance a digital twin played a role behind the scenes.

If you want to stay prepared for the future, keep learning about digital technologies. Because the world ahead will belong to those who understand how the digital and physical worlds connect.

I love the example of the washing machine! It shows how digital twins can simplify troubleshooting and avoid costly mistakes. As this technology grows, I think we’ll see more industries adopt it for testing and predictive maintenance.

I love the example of the washing machine—it’s such a simple yet effective way to explain the value of digital twins! It’s exciting to think about how this technology could evolve to help us predict and prevent issues in everything from appliances to even our health.